At CSTP Langat, the wastewater treatment process begins with primary treatment, where large debris and suspended solids are removed through screening and sedimentation. The effluent then undergoes secondary treatment, which involves biological processes to break down organic matter and reduce contaminants. Afterward, the effluent shifts to the dewatering process, where the separation between solid and liquid occured.

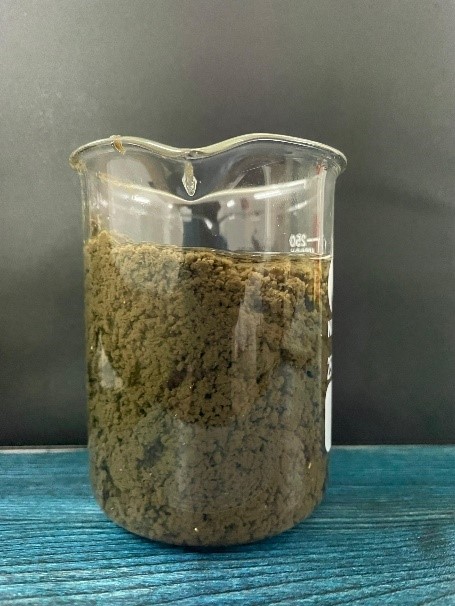

One of the critical processes at CSTP Langat is sludge treatment, which involves a dewatering process to reduce moisture content. The dewatering process need to produce sludge cake with a dryness level of more than 20% which to make it easier to handle and dispose of. Other than that, the plant needs to produce approximately 40 to 60 tonnes of sludge cake per day ensuring efficient sludge management and compliance with disposal regulations.

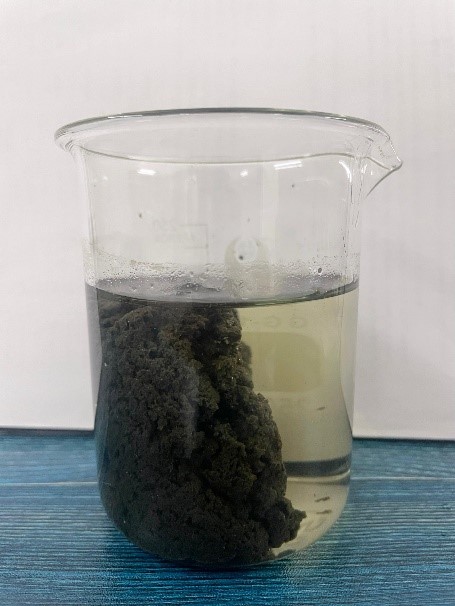

To enhance sludge treatment efficiency, GEO provides NEOFLOC 6650C polymer and technical assistance at CSTP Langat. NEOFLOC 6650C plays a crucial role in floc formation which improving sludge settling and compaction. Additionally, it supports both the thickening and dewatering processes, ensuring that the plant consistently achieves its target sludge dryness. By optimizing polymer performance and application, CSTP Langat can improve overall efficiency, reduce chemical consumption, and maintain high operational standards.

Challenges

One of the primary challenges was achieving consistent sludge dryness. The plant aimed to produce sludge cake with more than 20% dryness, but fluctuating sludge feed inflow and varying sludge characteristics made it difficult to maintain consistent results.

Another challenge was the optimization of polymer dosage. Determining the right dosage was complex as both over-dosing and under-dosing could lead to inefficiencies.

Solution

Continuous monitoring and fine-tuning of the NEOFLOC 6650C polymer dosage were essential to achieve consistent sludge dryness. This allowed for adjustments to the chemical balance based on variations in sludge composition and wastewater inflow, ensuring the target dryness of over 20% was consistently met.

To optimize the polymer dosage at CSTP Langat, GEO provided technical consultancy and conducted a series of trials to determine the most efficient dosage. These trials helped identify the optimal polymer setting, ensuring that the required sludge dryness of over 20% was consistently achieved without the risk of over-dosing or under-dosing. By fine-tuning the dosage based on sludge characteristics, the trials enabled the plant to use the exact amount of polymer needed, avoiding excess chemical use and achieving cost savings.

Key Figures

Scope:

GEO is responsible for optimizing the sludge thickening and dewatering process at CSTP Langat ensuring the plant achieves over 20% sludge dryness consistently. This includes supplying NEOFLOC polymer to enhance floc formation, sludge settling, and dewatering efficiency. Additionally, GEO provides technical support, conducting trials, monitoring polymer dosage, and making real-time adjustments to prevent over-dosing or under-dosing.

Achievements:

The implementation of NEOFLOC significantly improved sludge treatment efficiency ensuring consistent performance and cost savings. Other than that, GEO successfully identified the optimal polymer dosage and reduced the chemical consumption while maintaining effective sludge thickening and dewatering process.

Sludge:

For the thickening process, the incoming sludge feed has a dry solid (DS) content of around 1%. While for the dewatering process, the sludge feed contains approximately 2% DS. This %DS of sludge feed is neither too high nor too low, but it directly affects polymer consumption.